Centerless grinding is a unique machining process that enables manufacturers to rapidly create high-quality precision parts. At EMC Precision, we invest in cutting-edge centerless grinding equipment to produce parts at tight tolerances down to ± 0.00005”. By utilizing robotic loading and unloading, this equipment lowers production costs while exceeding the precision and accuracy of conventional machining processes.

Centerless grinding is a unique machining process that enables manufacturers to rapidly create high-quality precision parts. At EMC Precision, we invest in cutting-edge centerless grinding equipment to produce parts at tight tolerances down to ± 0.00005”. By utilizing robotic loading and unloading, this equipment lowers production costs while exceeding the precision and accuracy of conventional machining processes.

What Is Centerless Grinding?

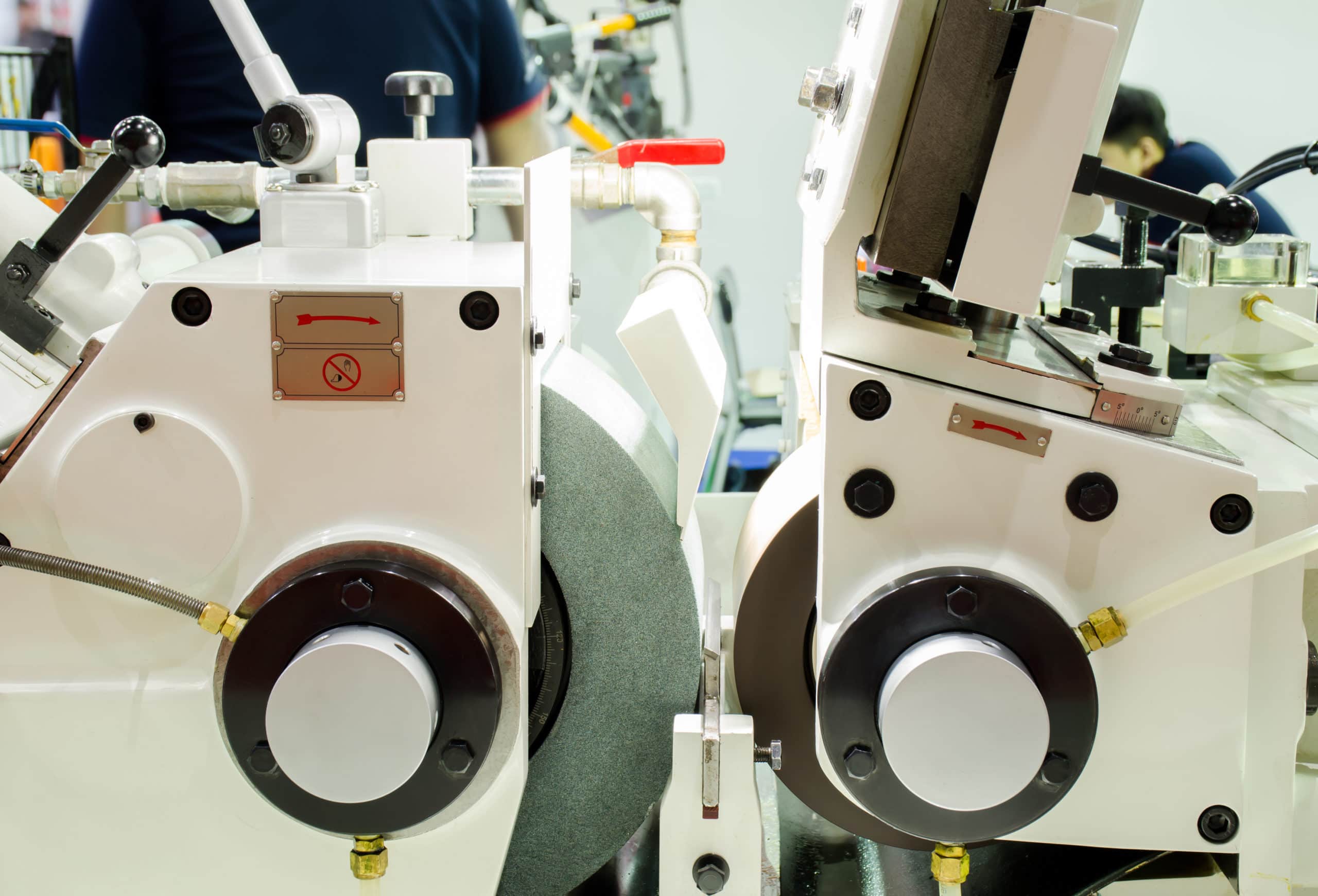

Centerless grinding uses two wheels to remove material from a workpiece, resulting in a rounded final part. The workpiece, between the two wheels, stays in place on an angled workblade. Depending on the configuration, the workpiece can rest on the centerline or below the center of the wheels.

The larger, abrasive grinding wheel rotates at high speeds, removing material from the workpiece. The smaller regulating wheel adjusts the workpiece’s position by rotating more slowly. Together, these wheels shape the outer diameter of the workpiece into the desired final product.

Although the lack of center may seem to compromise the precision of the workpiece, centerless grinding is one of the most precise and controllable metalworking processes. The accuracy and speed of centerless grinding make it ideal for use across a range of industries and applications. Some products that are manufactured using centerless grinding include:

- Axles

- Bearings

- Bushings

- Balls

- Crankshafts

- Injector needles

- Motor shafts

- Valve pistons

- Piston pins

Centerless Grinding Service

At EMC Precision, our centerless grinding services are ISO 9001 and IATF 16949 certified. We utilize state-of-the-art tools and technology to deliver precision parts with extremely tight tolerances. With metrology equipment such as air gauges, roundness testers, profilometers, and CMMs, we provide high-quality analytics and quality control inspections. These advantages help reduce production costs and create consistent results on both small and large production runs. We work with multiple types of metals, including:

- Aluminum

- Alloy steel

- Stainless steel

- Copper

- Carbon steel

Our centerless grinding equipment has robotic loading and unloading capabilities, as well as CNC dresser heads. We work with our customers to create custom parts at tolerances of 2.5 microns (± 0.00005″).

With both through-feed and profile centerless grinding capabilities, we can take on projects with challenging requirements for surface quality, size, or concentricity. To ensure accuracy, we closely monitor every step of the process, from feed rate to wheel force to rotational speed to dressing method. This careful attention to detail enables us to produce parts at high volumes without sacrificing quality or accuracy.

Centerless Grinding Advantages

Centerless grinding is ideal for applications requiring straight lines, tight tolerances, and smooth finishes. Because it can achieve such high levels of precision, centerless grinding is a common machining process for making aerospace, medical, and automotive parts.

The following are some of the most significant advantages of centerless grinding.

- Automation: Operators can set up the equipment for automatic material feeding, which improves production speeds, reduces labor costs, and minimizes the possibility of human error.

- Fast loading: Since centerless grinding drastically shortens loading times, operators can run continuous high-speed grinding production.

- High production: With automated feeding and quick loading times, centerless grinding can produce parts at a rapid rate, sometimes up to 300 parts per minute.

- Long lifespan: The equipment for centerless grinding tends to have a long lifespan and high levels of durability. This is largely due to the fact that this process does not require centering or external feeding. Centerless grinding equipment also requires very little maintenance after its initial setup, which further reduces costs.

- No axial thrust: Because it does not put pressure on the ends of the workpiece, centerless grinding eliminates the possibility of inaccuracies or damage resulting from axial thrust, especially on fragile or brittle substrates.

- No deflection: The regulating wheel constantly supports the workpiece, so deflection does not occur in centerless grinding as it may in centered grinding.

- Tight tolerances: Centerless grinding can produce parts at extremely tight dimensional tolerances, even when working with complex designs or at high volumes.

Centerless Grinding Techniques

Centerless grinding may utilize any of the following specific techniques to produce precision parts.

Through-Feed

Ideal for cylindrical parts, this technique involves feeding the workpiece directly through the two wheels. Through-feed centerless grinding does not require a feeding mechanism, as the regulating wheel automatically moves the workpiece along. This is the most popular centerless grinding technique.

End-Feed

In end-feed centerless grinding, the workpiece moves through the grinding system until it comes in contact with an end stop. It undergoes the grinding process before moving back out. End-feeding is better suited for tapered parts.

In-Feed

In-feed centerless grinding is typically reserved for unusually shaped workpieces with varying diameters—such as hourglass shapes—as the technique requires the operator to manually place the workpiece into the grinding apparatus. The operator will then observe the workpiece throughout the grinding process, ensuring its shape and contours are properly machined.

Centerless Grinding at EMC Precision

Centerless grinding is a versatile and precise metalworking process that offers advantages for a wide range of industrial applications. Since 1925, EMC Precision has been providing precision machining services with excellent turnaround times and a dedication to customer service. We work with both large and small production runs, enabling us to meet the needs of diverse customers. No matter how complex your project is, our skilled team will work closely with you to provide the lowest costs, answer your questions, and deliver high-quality goods. EMC Precision currently offers centerless grinding specifically for products we produce for our customers.

To begin working with us on your next centerless grinding project, request a quote today.