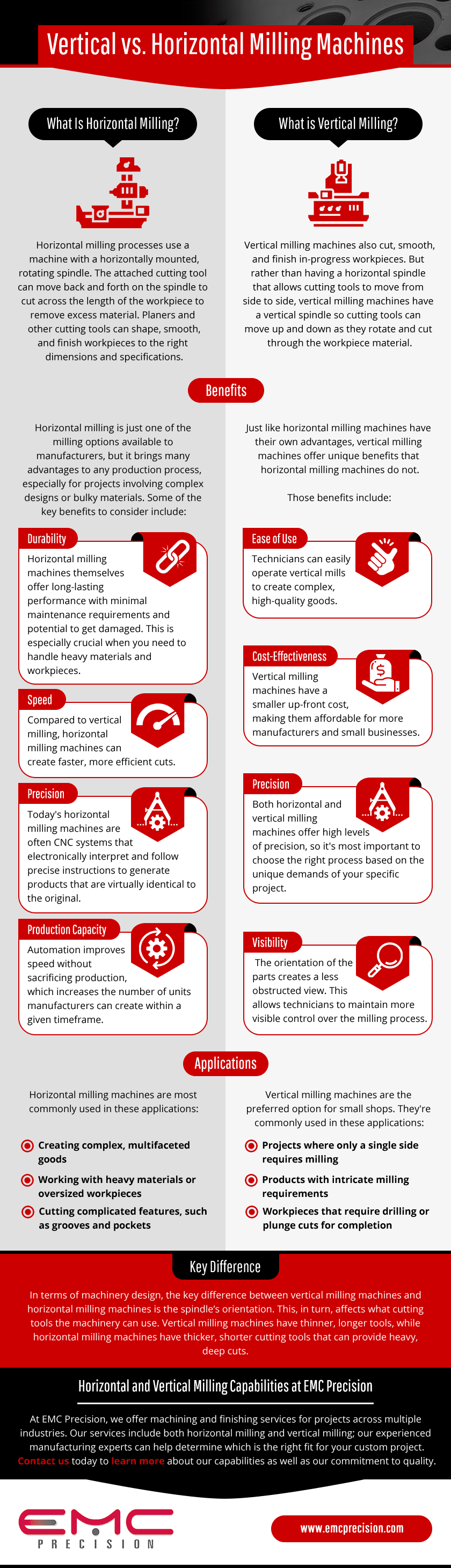

Milling is a precise machining technique that removes excess material from an in-process workpiece. It comes in two broad varieties: horizontal milling and vertical milling. Keep reading to learn more about the differences between the two techniques, their unique advantages, and common applications for each milling process.

What Is Horizontal Milling?

Horizontal milling processes use a machine with a horizontally mounted, rotating spindle. The attached cutting tool can move back and forth on the spindle to cut across the length of the workpiece to remove excess material. Planers and other cutting tools can shape, smooth, and finish workpieces to the right dimensions and specifications.

Horizontal Milling Benefits and Applications

Horizontal milling is just one of the milling options available to manufacturers, but it brings many advantages to any production process, especially for projects involving complex designs or bulky materials. Some of the key benefits to consider include:

- Durability: Horizontal milling machines themselves offer long-lasting performance with minimal maintenance requirements and potential to get damaged. This is especially crucial when you need to handle heavy materials and workpieces.

- Speed: Compared to vertical milling, horizontal milling machines can create faster, more efficient cuts. These complex machines can even manage multiple cuts at once and remove pocketing or facing chips so there’s no interruption to the work cycle.

- Precision: Today’s horizontal milling machines are often CNC, or computer numeric control, equipment. CNC systems electronically interpret and follow precise instructions to generate products that are virtually identical to the original. Horizontal CNC milling processes ensure high-quality production within tight tolerances.

- Production Capacity: Automation improves speed without sacrificing production, which increases the number of units manufacturers can create within a given timeframe. Combining that with the fact that automated processes minimize interruptions means a significantly increased ability to produce more goods in less time.

Horizontal milling machines are most commonly used in these applications:

- Creating complex, multifaceted goods

- Working with heavy materials or oversized workpieces

- Cutting complicated features, such as grooves and pockets

What Is Vertical Milling?

Vertical milling machines also cut, smooth, and finish in-progress workpieces. But rather than having a horizontal spindle that allows cutting tools to move from side to side, vertical milling machines have a vertical spindle so cutting tools can move up and down as they rotate and cut through the workpiece material.

Vertical milling tools are more popular than horizontal alternatives. They also come in two main varieties:

1. Bed milling machines: In these machines, the material moves perpendicularly. While the bed of the mill maneuvers along Y and Z axes, the spindle can maneuver across the X-axis. This allows the machine to create complex, three-dimensional products.

2. Turret milling machines: These compact machines have a fixed spindle and bed that can move both horizontally and perpendicularly to provide the greatest versatility. These machines work best for small products.

Vertical Milling Benefits and Applications

Just like horizontal milling machines have their own advantages, vertical milling machines offer unique benefits that horizontal milling machines do not. Those benefits include:

- Ease of Use: Technicians can easily operate vertical mills to create complex, high-quality goods.

- Cost-Effectiveness: Vertical milling machines have a smaller up-front cost, making them affordable for more manufacturers and small businesses.

- Precision: Both horizontal and vertical milling machines offer high levels of precision, so it’s most important to choose the right process based on the unique demands of your specific project.

- Visibility: The orientation of the parts creates a less obstructed view. This allows technicians to maintain more visible control over the milling process.

Vertical milling machines are the preferred option for small shops. They’re commonly used in these applications:

- Projects where only a single side requires milling

- Products with intricate milling requirements

- Workpieces that require drilling or plunge cuts for completion

Differences Between Vertical and Horizontal Milling Machines

In terms of machinery design, the key difference between vertical milling machines and horizontal milling machines is the spindle’s orientation. This, in turn, affects what cutting tools the machinery can use. Vertical milling machines have thinner, longer tools, while horizontal milling machines have thicker, shorter cutting tools that can provide heavy, deep cuts.

Horizontal and Vertical Milling Capabilities at EMC Precision

At EMC Precision, we offer machining and finishing services for projects across multiple industries. Our services include both horizontal milling and vertical milling; our experienced manufacturing experts can help determine which is the right fit for your custom project. Contact us today to learn more about our capabilities as well as our commitment to quality.