Tempering vs Annealing: What’s the Difference?

Leave a Comment

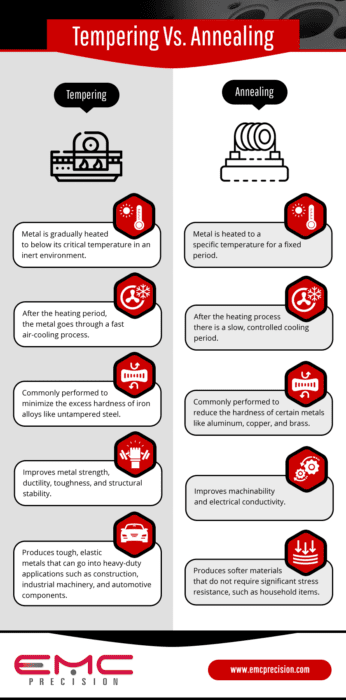

Annealing and tempering are both heat treating methods that prepare metals for manufacturing. Through heat treatment, high temperatures change the physical, chemical, and mechanical properties of steel, stainless steel, and steel alloys, increasing their performance and durability. Heat treatment can impact other properties of a metal product as well, including strength, malleability, ductility, formability, and hardness.

Tempering and annealing differ in their cooling and heating rates, thus producing different end products. In this blog post, we’ll discuss more similarities and differences between these two processes.

What Is Tempering?

Tempering heats the metal below its critical temperature, usually in an inert environment. The temperature varies depending on the levels of hardness that need to be reduced. Higher temperatures reduce hardness and boost elasticity and plasticity while reducing tensile strength and yield. In lower temperatures, the metal maintains its hardness but will no longer be brittle.

In tempering, the metal must be heated gradually to avoid cracking. Once the proper temperature is reached, it should be maintained for a set amount of time. Generally, this means one hour for each inch of thickness, but this differs according to the metal type. After the heat relieves internal stresses, the metal goes through a fast air-cooling process.

Tempering is commonly performed to minimize the excess hardness of iron alloys like untampered steel, which is usually too hard and brittle to apply in most industrial applications. Tempering also improves metal strength, ductility, toughness, and structural stability.

What Is Annealing?

Annealing involves heating metal to a specific temperature for a fixed period, followed by a slow, controlled cooling period. Annealing furnaces are large enough to facilitate proper airflow around the metal.

The main reason for annealing is to reduce the hardness of certain metals like aluminum, copper, and brass. As a result, annealing improves machinability and electrical conductivity.

Here are the three stages of the annealing process:

- Recovery: This initial stage heats the metal to relax and repair its internal structures.

- Recrystallization: During this stage, the metal is continuously heated at a temperature greater than its recrystallization temperature but less than its melting point. This allows new grains to develop in the metal’s internal structure without stresses.

- Grain growth: The slow cooling stage facilitates the development of grains, producing a softer, more ductile metal.

The annealing process softens metals to allow for effective cold working, eliminating the mechanical stresses that result from grinding or machining. Without annealing, cold working can lead to cracking.

Tempering Vs. Annealing

Tempering produces tough, elastic metals that can go into heavy-duty applications such as construction, industrial machinery, and automotive components. Therefore, tempering reduces the hazards of working in these environments.

In contrast, annealing produces softer materials that do not require significant stress resistance, such as household items.