Automated Manufacturing Benefits and Outcomes

Leave a CommentAutomation is the defining factor for product manufacturing in the 21st century. As automation technology becomes smaller, faster, and more precise, manufacturers are increasingly incorporating automated systems to shorten turnaround times, enhance productivity, and improve product quality. In fact, automation is becoming crucial for manufacturers who want to remain competitive in an evolving industry.

At EMC Precision, we understand the value of lean manufacturing and automation in today’s manufacturing market. With more than seven decades of experience, we have the knowledge, skills, and technology necessary to manufacture precision products for a wide variety of applications and industries. In this blog, we discuss the benefits of automated manufacturing and the positive outcomes they create for businesses and customers alike.

What Is Automated Manufacturing?

Automation uses computerized software to direct production equipment and operating systems. With the right automation technology, manufacturers enhance their overall efficiency by increasing production capacity and reducing operating costs.

Automated manufacturing incorporates specialized production management software and robotics technology to produce physical products with fewer tools. Whereas more traditional manufacturing processes use a different tool for each operation, automated manufacturing increases the number of operations that a given tool or system can perform.

With greater tool flexibility, manufacturers can produce more products at higher speeds than with manually-operated systems. With this kind of performance enhancement, it is more important than ever for manufacturers to upgrade to automated systems. In fact, more than 75% of manufacturers currently use some form of automation to improve their productivity and scale their operations.

At EMC Precision, we make it a priority to stay apprised of the latest developments in manufacturing automation to ensure we provide our customers with the latest products and services. We understand that the manufacturing industry is ever-evolving, and it is our goal to remain at the forefront of manufacturing technology with cutting-edge robotics and automated systems that speed and streamline operations and produce superior product quality.

Benefits of Automated Manufacturing

Automated manufacturing has grown increasingly popular in recent years due to the many advantages it offers. Some of the primary benefits of process automation in manufacturing include:

Improved Workplace Safety

Since OSHA was established in 1970, manufacturers have prioritized workplace safety. By moving dangerous or repetitive tasks to automated equipment, you reduce the potential for workplace accidents. Workers can operate automated equipment from a distance, rather than being in direct contact with dangerous components. In addition, workers are less likely to lose focus and make careless mistakes if repetitive and mundane tasks are handled by automation.

Enhanced Labor Productivity

Automated systems increase your manufacturing speeds without compromising quality. When you use automation for monotonous, boring tasks, you free up your workers for more interesting tasks and operations that cannot be automated. In addition, many modern manufacturing operations such as rapid prototyping, 3D printing, PLC surfacing, CNC machining, and PCB printing simply can’t be completed without the use of automation.

Reduced Operating Costs

Incorporating manufacturing process automation into your facility’s operations streamlines your workflow and speeds your overall processes. This leads to reduced lead times, significant energy savings, and lower labor costs, which boost your bottom line. Automation and robotics equipment are also extremely accurate, which mitigates the potential for costly errors and virtually eliminates material waste.

Greater Accuracy

While a seasoned lathe operator or machinist can create accurate components, manual tooling is no match for automated systems, particularly with regard to accuracy and speed. As products become smaller and more dependent on miniaturized components, manual labor grows less effective and efficient. With automated manufacturing, we create products more quickly, within extremely tight tolerances, and with a high degree of repeatability that cannot be accomplished through manual machining processes.

Automated Manufacturing at EMC Precision

EMC Precision is a leading manufacturer of parts and components for customers in every industry. We are dedicated to helping our customers reduce costs, enhance efficiency, improve quality, and facilitate optimal worker safety through the use of state-of-the-art automated systems. Our capabilities include CNC machining, centerless grinding, heat treatments, hard chrome plating, and assembly. We also offer value-added finishing and assembly services for your convenience.

EMC’s lean manufacturing facility is specifically engineered to produce only the highest quality parts with the utmost speed and precision. We are committed to excellence, with established best practices and testing protocols at every step of the design and manufacturing process.

Reach Out to Our Experts Today!

When you partner with EMC Precision, you benefit from decades of manufacturing experience coupled with the latest automation and robotics technology. No matter how complex your requirements are, we have the knowledge, skill, and equipment to complete your project quickly and efficiently.

To learn more about ways that automated manufacturing can help your business, contact us today!

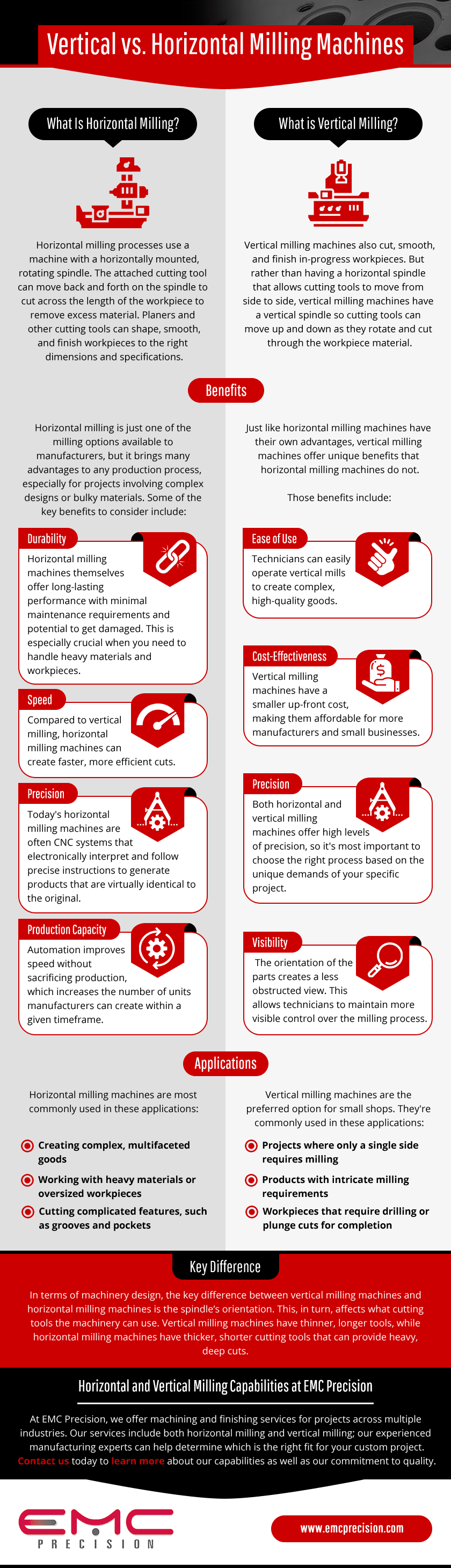

Vertical vs. Horizontal Milling Machines

Leave a CommentMilling is a precise machining technique that removes excess material from an in-process workpiece. It comes in two broad varieties: horizontal milling and vertical milling. Keep reading to learn more about the differences between the two techniques, their unique advantages, and common applications for each milling process.

What Is Horizontal Milling?

Horizontal milling processes use a machine with a horizontally mounted, rotating spindle. The attached cutting tool can move back and forth on the spindle to cut across the length of the workpiece to remove excess material. Planers and other cutting tools can shape, smooth, and finish workpieces to the right dimensions and specifications.

Horizontal Milling Benefits and Applications

Horizontal milling is just one of the milling options available to manufacturers, but it brings many advantages to any production process, especially for projects involving complex designs or bulky materials. Some of the key benefits to consider include:

- Durability: Horizontal milling machines themselves offer long-lasting performance with minimal maintenance requirements and potential to get damaged. This is especially crucial when you need to handle heavy materials and workpieces.

- Speed: Compared to vertical milling, horizontal milling machines can create faster, more efficient cuts. These complex machines can even manage multiple cuts at once and remove pocketing or facing chips so there’s no interruption to the work cycle.

- Precision: Today’s horizontal milling machines are often CNC, or computer numeric control, equipment. CNC systems electronically interpret and follow precise instructions to generate products that are virtually identical to the original. Horizontal CNC milling processes ensure high-quality production within tight tolerances.

- Production Capacity: Automation improves speed without sacrificing production, which increases the number of units manufacturers can create within a given timeframe. Combining that with the fact that automated processes minimize interruptions means a significantly increased ability to produce more goods in less time.

Horizontal milling machines are most commonly used in these applications:

- Creating complex, multifaceted goods

- Working with heavy materials or oversized workpieces

- Cutting complicated features, such as grooves and pockets

What Is Vertical Milling?

Vertical milling machines also cut, smooth, and finish in-progress workpieces. But rather than having a horizontal spindle that allows cutting tools to move from side to side, vertical milling machines have a vertical spindle so cutting tools can move up and down as they rotate and cut through the workpiece material.

Vertical milling tools are more popular than horizontal alternatives. They also come in two main varieties:

1. Bed milling machines: In these machines, the material moves perpendicularly. While the bed of the mill maneuvers along Y and Z axes, the spindle can maneuver across the X-axis. This allows the machine to create complex, three-dimensional products.

2. Turret milling machines: These compact machines have a fixed spindle and bed that can move both horizontally and perpendicularly to provide the greatest versatility. These machines work best for small products.

Vertical Milling Benefits and Applications

Just like horizontal milling machines have their own advantages, vertical milling machines offer unique benefits that horizontal milling machines do not. Those benefits include:

- Ease of Use: Technicians can easily operate vertical mills to create complex, high-quality goods.

- Cost-Effectiveness: Vertical milling machines have a smaller up-front cost, making them affordable for more manufacturers and small businesses.

- Precision: Both horizontal and vertical milling machines offer high levels of precision, so it’s most important to choose the right process based on the unique demands of your specific project.

- Visibility: The orientation of the parts creates a less obstructed view. This allows technicians to maintain more visible control over the milling process.

Vertical milling machines are the preferred option for small shops. They’re commonly used in these applications:

- Projects where only a single side requires milling

- Products with intricate milling requirements

- Workpieces that require drilling or plunge cuts for completion

Differences Between Vertical and Horizontal Milling Machines

In terms of machinery design, the key difference between vertical milling machines and horizontal milling machines is the spindle’s orientation. This, in turn, affects what cutting tools the machinery can use. Vertical milling machines have thinner, longer tools, while horizontal milling machines have thicker, shorter cutting tools that can provide heavy, deep cuts.

Horizontal and Vertical Milling Capabilities at EMC Precision

At EMC Precision, we offer machining and finishing services for projects across multiple industries. Our services include both horizontal milling and vertical milling; our experienced manufacturing experts can help determine which is the right fit for your custom project. Contact us today to learn more about our capabilities as well as our commitment to quality.

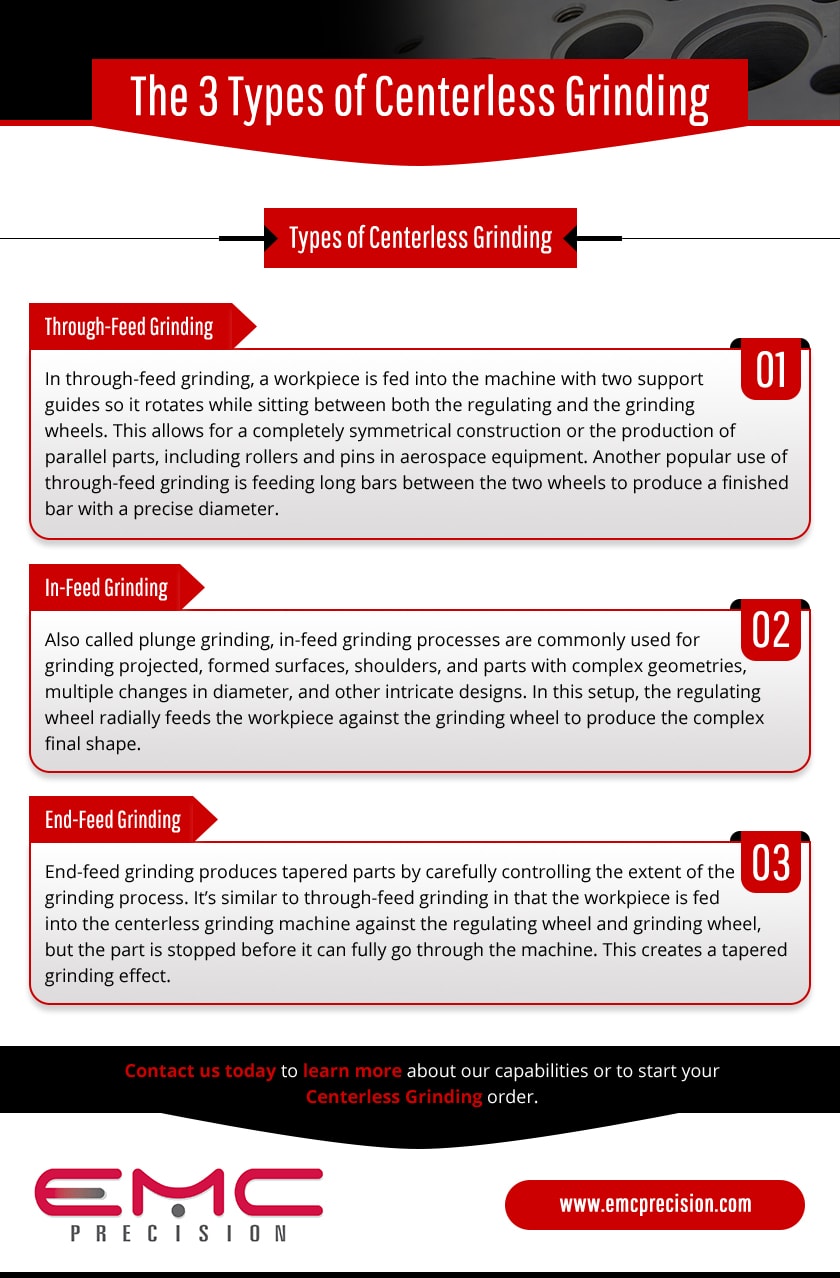

The 3 Types of Centerless Grinding

Leave a Comment

Machined and fabricated products often need to undergo grinding processes before they can be considered complete. Not only does grinding remove rough patches and dangerously sharp edges, but it can also change the contours of the product. Centerless grinding is a versatile, popular grinding process that can be used to make in-process goods with rounded surfaces and dimensions that fall squarely within tight tolerances. There are three main types of centerless grinding that manufacturers use. Learn more about centerless grinding overall and these three types to choose the right fit for your next manufacturing project.

What Is Centerless Grinding?

Centerless grinding processes remove excess material from a workpiece by filing it away with a grinding wheel until the product that remains has the right surface attributes and dimensions. In a centerless grinding machine, the workpiece is secured near two grinding wheels. These are the regulating wheel and the actual grinding wheel, which grinds against the outer diameter of the piece. Centerless grinding offers a smooth product finish. It’s also extremely accurate and can produce pieces with both straight lines and dimensions that meet the product specifications within tight tolerances.

Types of Centerless Grinding

Manufacturers can choose between three different types of centerless grinding to create products with different attributes.

1. Through-Feed Grinding

In through-feed grinding, a workpiece is fed into the machine with two support guides so it rotates while sitting between both the regulating and the grinding wheels. This allows for a completely symmetrical construction or the production of parallel parts, including rollers and pins in aerospace equipment. Another popular use of through-feed grinding is feeding long bars between the two wheels to produce a finished bar with a precise diameter.

2. In-Feed Grinding

Also called plunge grinding, in-feed grinding processes are commonly used for grinding projected, formed surfaces, shoulders, and parts with complex geometries, multiple changes in diameter, and other intricate designs. In this setup, the regulating wheel radially feeds the workpiece against the grinding wheel to produce the complex final shape.

3. End-Feed Grinding

End-feed grinding produces tapered parts by carefully controlling the extent of the grinding process. It’s similar to through-feed grinding in that the workpiece is fed into the centerless grinding machine against the regulating wheel and grinding wheel, but the part is stopped before it can fully go through the machine. This creates a tapered grinding effect.

Advantages of Centerless Grinding

Centerless grinding is a popular and effective method for shaping in-process metal parts into precise products. Some of the key advantages of choosing centerless grinding include:

- Speed: Centerless grinding machines have short loading times, so orders can be processed on a tight schedule.

- Volume: Large centerless grinding machines can grind high-order volumes. This results in large quantities of virtually identical metal pieces.

- Error Reduction: One of the main attributes of centerless grinding is that there is no risk of deflection.

- Long Life Span: Centerless grinding processes create a smooth finish and a controlled shape without putting too much pressure on the metal material. This results in a finished product with a longer life and less risk of breakage.

Choose Centerless Grinding Capabilities from EMC Precision

At EMC Precision, we serve our clients with precision machining, assembling capabilities, and other value-added services, including centerless grinding services. This value-added service, while not available as a standalone offer, enables us to take on the most challenging requirements for size, surface quality, concentricity, and more:

- Accuracy at tolerances—to .0001—exceeding conventional machining capabilities

- State-of-the-art automated loading and CNC dresser heads

- Consistent quality in the process saves cost

Contact us today to learn more about our CNC machining capabilities or to inquire about our centerless grinding service.