Value-Added Services

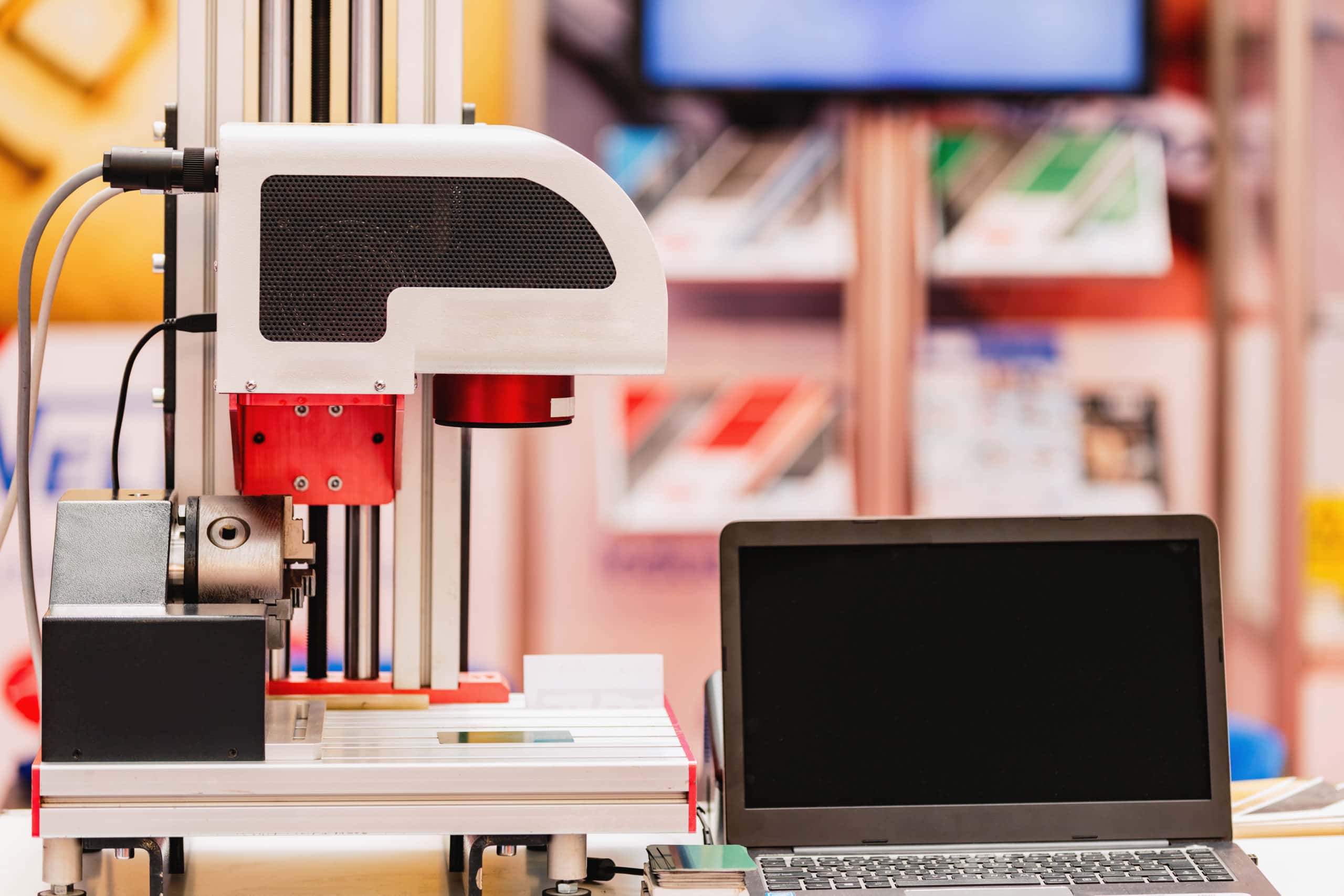

At EMC Precision, we invest in the mechanical advantages of lean manufacturing to deliver value-added performance. In addition to our core manufacturing capabilities (CNC machining and centerless grinding), we offer a range of value-added services to ensure our customers receive complete solutions for their business needs. These include CNC honing, finishing, and assembly and packaging.

Our CNC Honing Capabilities

Honing is a manufacturing process that involves moving an abrasive element (e.g., a honing stone) across a surface to improve its geometric form or texture. CNC honing utilizes computer-controlled technology to move the element along a controlled path, ensuring better accuracy and precision. It is ideal for producing high-quality engineered parts.

The experts at EMC Precision offer CNC honing capabilities to exact inner diameters. We can achieve surface finishes to 4 micro and .0001 tolerances. By using CNC-enabled technology, we ensure we get the best results every time, resulting in better accuracy, consistency, and quality.

Our Part Finishing Capabilities

Our partnerships with industry-leading companies enable us to provide specialized capabilities. We can guarantee that all of our supply chain partners will provide the highest-quality service when working with customers.

We maintain a broad selection of industrial coating and finishing services. These include:

- Anodizing. This electrochemical surface finishing process creates a durable and decorative anodic oxide finish on metal surfaces. It provides a corrosion-resistant layer that cannot chip or peel.

- Passivation. This stainless steel surface treatment process removes iron from the material’s surface and prompts the formation of an oxide layer, both of which protect against corrosion.

- Electropolishing. This polishing process uses an electrical current to remove material from the surface of machined components, resulting in a smooth and polished finish.

- Phosphating. This metal conversion process converts steel surfaces to iron phosphate. It is often used as a pretreatment before other corrosion protection operations.

- Nickel and zinc plating. Plating is a metal finishing process that involves depositing thin layers of coating material onto the surface of the substrate. The properties of the layer depend on the coating material. For example, nickel offers increased wear resistance, while zinc offers increased corrosion resistance.

Our Sub-Assembly & Packaging Capabilities

Once all components for an order are fully machined and finished, we can assemble, kit, package, and ship them as needed.

Why Work With EMC Precision?

At EMC Precision, we are a one-stop-shop for all precision machined component needs. By providing machining, finishing, assembly, packaging, and shipping capabilities, we can offer streamlined production solutions that save you time and money.

Throughout our years in business, we’ve carefully enhanced and refined our processes to better meet our customers’ machining and manufacturing requirements. Our lean, optimized processes help reduce production costs and lead times, ensuring an effective and efficient solution for all part and product manufacturing needs. Customers know they can count on us to deliver the goods and services they need for their projects.

To learn more about our capabilities or discuss your project requirements with one of our team members, contact us today.